Industry Standards and Regulations: The Importance of Cleanroom Apparel Across Sectors

Published by Harmony Lab & Safety Supplies on Mar 13, 2025

Industry Standards and Regulations: The Importance of Cleanroom Apparel Across Sectors

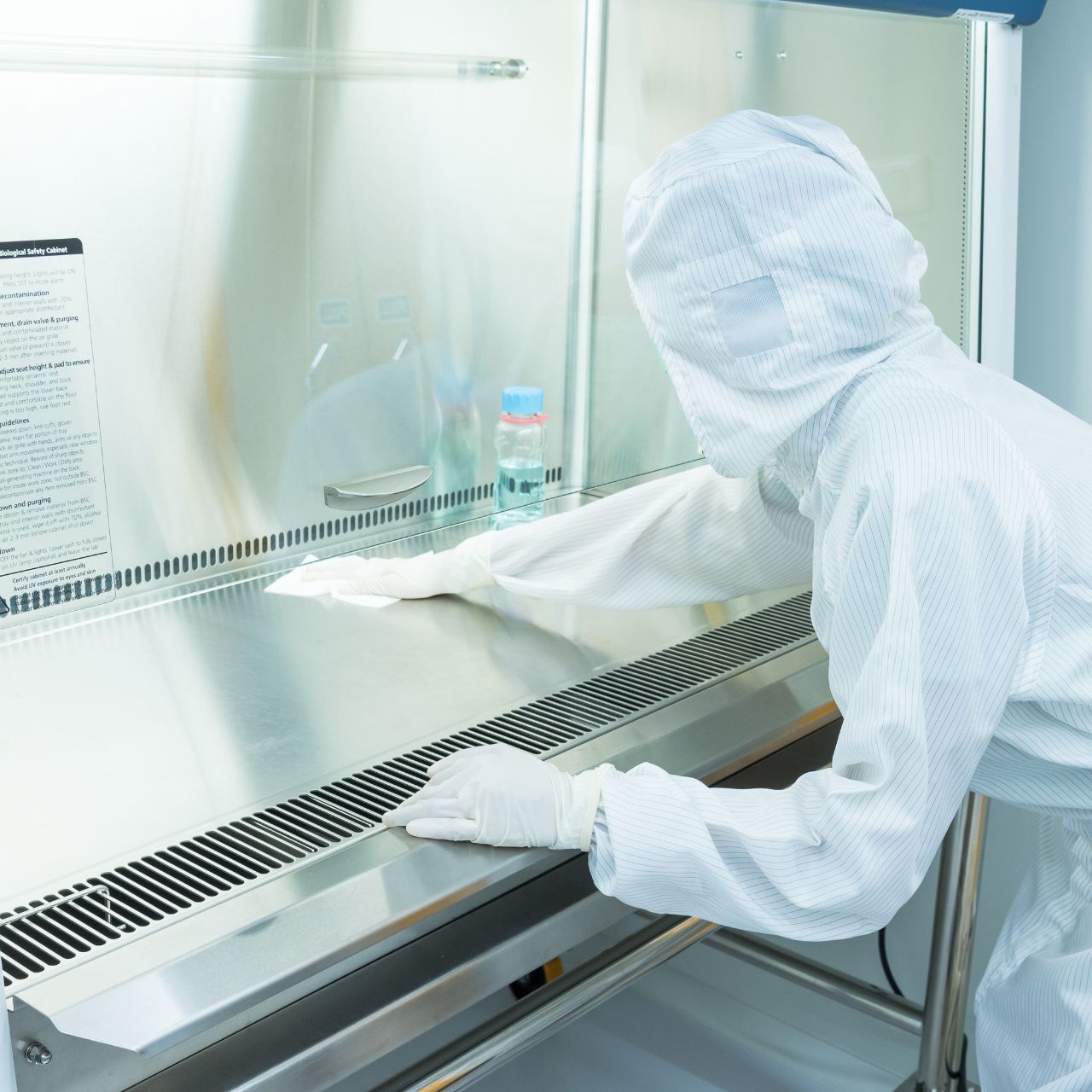

Cleanrooms are controlled environments designed to minimize contamination, and cleanroom apparel plays a crucial role in maintaining the required air quality. This specialized clothing acts as a critical barrier, preventing the introduction of pollutants like dust, microbes, vapors, and aerosol particles from personnel into these sensitive areas. While the fundamental purpose of cleanroom apparel remains consistent across industries, the specific requirements for this apparel are heavily influenced by industry-specific standards and regulations. Let's explore the importance of cleanroom apparel in various sectors and the guidelines that govern their selection and use.

Defining Cleanroom Apparel

Cleanroom apparel encompasses the specialized clothing worn by individuals working within cleanrooms. These garments are made from materials designed to limit particle dispersion from employees into the environment. The type of apparel required can range from simple cleanroom face masks, shoe covers, and lab coats to full-body suits, depending on the level of cleanliness mandated for the specific cleanroom.

Cleanroom Classifications and Apparel

Cleanrooms are categorized by their cleanliness level, most commonly defined by ISO standards (ISO 14644-1). The common levels include ISO Class 4 (Class 10), ISO Class 5 (Class 100), ISO Class 6 (Class 1000), ISO Class 7 (Class 10,000), and ISO Class 8 (Class 100,000). Different industries have varying needs for cleanliness and sterility, which directly dictate the type of cleanroom apparel that must be worn.

Cleanroom Apparel for Different ISO Classes

The stringency of the cleanroom classification directly correlates with the extent of body coverage required by the apparel:

- ISO Class 8 (Class 100,000): Often the least strict, this class typically requires a bouffant cap, a frock or lab coat, shoe covers, a face mask, and gloves.

- ISO Class 7 (Class 10,000): May necessitate additional coverage, potentially including full arm and leg coverage.

- ISO Class 6 (Class 1,000) & ISO Class 5 (Class 100): These stricter environments demand more comprehensive coverage, often including coveralls, hoods, and dedicated cleanroom footwear.

- ISO Class 4 (Class 10) & ISO Class 3 (Class 1): Representing the most stringent cleanliness levels, these classes typically require complete body coverage. This includes a hood, bouffant cap, coverall, intersect under coverall, boot covers, goggles, a face mask, and gloves, effectively encapsulating the worker to minimize any potential for contamination.

Cleanroom Apparel Across Sectors

Let's delve into how specific industries approach cleanroom apparel based on their unique requirements and regulations:

Pharmaceutical Industry

The pharmaceutical industry operates under stringent regulations like Good Manufacturing Practices (GMP). These regulations mandate sterile environments for the production of medications. Consequently, cleanroom apparel in this sector often requires complete body coverage with sterile garments, including sterilized coveralls, hoods, masks, gloves, and boots. The focus is on preventing any microbial contamination that could compromise the safety and efficacy of pharmaceutical products.

Electronics Manufacturing

In electronics manufacturing, even microscopic particles can cause defects in sensitive components. Therefore, the primary concern is particulate contamination and electrostatic discharge (ESD). Cleanroom apparel in this industry emphasizes low-linting materials and often includes features like conductive fibers to dissipate static charges. Garments like smocks, coveralls, gloves, finger cots, and specialized footwear are common to protect sensitive electronic devices.

Medical Device Manufacturing

Similar to the pharmaceutical industry, medical device manufacturing requires careful control of bioburden to ensure the safety of medical devices. Depending on the device's intended use and level of invasiveness, the requirements for cleanroom apparel can range from basic coverage (lab coats, shoe covers, masks) to more extensive coverage with sterile garments for devices that come into direct contact with patients.

Biotechnology and Research

Biotechnology and research facilities often have specific needs depending on the nature of their work. In some cases, the focus might be on preventing contamination of experiments, while in others, it might be on protecting personnel from potentially hazardous materials. Apparel choices can range from standard lab coats and gloves to specialized barrier gowns and respirators, depending on the specific risks involved.

Food and Beverage Industry

While not always classified under the same stringent ISO standards as pharmaceutical or electronics cleanrooms, the food and beverage industry utilizes controlled environments to prevent microbial contamination and allergens from entering the production process. Apparel in this sector typically includes hairnets, beard covers, lab coats or frocks, and shoe covers. The emphasis is on hygiene and preventing the shedding of hair and skin particles into food products.

Choosing Between Disposable and Washable Cleanroom Clothing

Cleanroom clothing can be either disposable or washable. Disposable garments are often preferred in higher-class cleanrooms due to the guaranteed cleanliness of a single-use item. Washable clothing, on the other hand, is specially laundered to remove contaminants and disinfect the material without degrading its protective properties. The choice often depends on the cleanroom classification, cost-effectiveness, and sustainability considerations. A combination of both types is also common.

How to Choose Cleanroom Clothing

Selecting the right cleanroom apparel involves considering several factors, including the material (woven or non-woven, flame-resistant, biohazard-resistant), the level of hazardous risk protection required, the necessary quantity and sizes, and whether disposable or washable options are most suitable for the application.

Conclusion

Cleanroom apparel is undeniably vital in controlling contamination within cleanroom environments. Understanding the specific requirements dictated by industry standards and regulations is essential for selecting the appropriate apparel. By carefully considering the ISO classification of the cleanroom and the specific needs of your industry, you can ensure a controlled and safe environment that meets the necessary cleanliness and sterility levels for your critical operations.