-

$34.99Ships within 1-2 Business Days

-

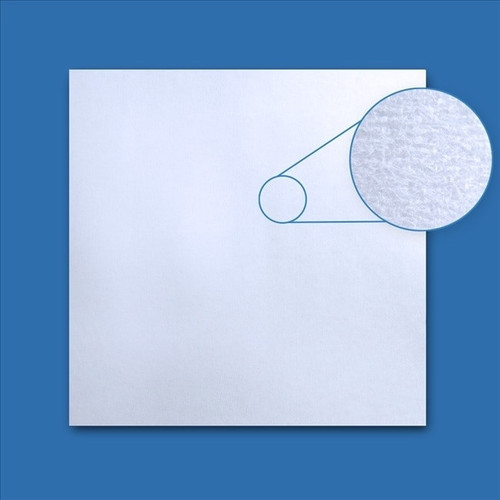

Teknipure

SKU: TC2PU1

TekniClean Knit Polyester Cleanroom Wipes, Ultrasonic Sealed Edge, Lint Free (4 Sizes)

$22.99Ships within 1-2 Business Days -

$25.99Ships within 1-2 Business Days

-

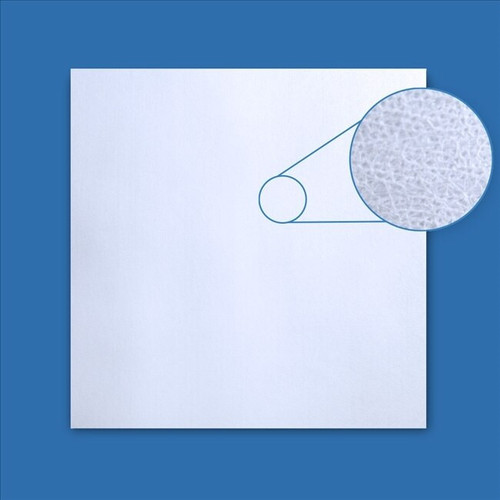

Teknipure

SKU: TC3PB1S

TekniClean ESD Safe Ultrasonic Border Sealed Polyester Knit Cleanroom Wipes, 2 Sizes

$28.90Ships within 1-2 Business Days -

$13.99Ships within 1-2 Business Days

-

$16.99Ships within 1-2 Business Days

-

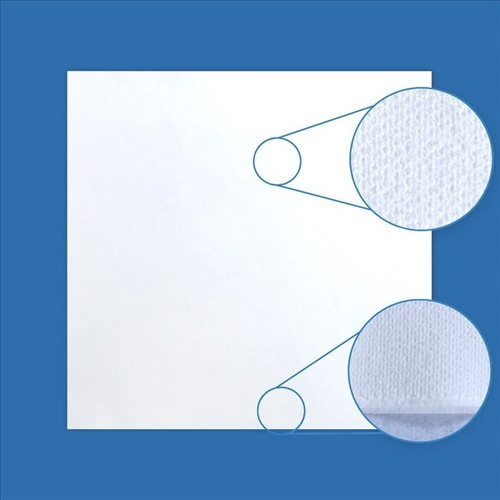

Teknipure

SKU: TC2PU3

TekniClean 2-Ply Quilted Polyester Ultrasonic Sealed Edge Cleanroom Wipers (3 Sizes)

$399.99Ships within 1-2 Business Days -

$24.99Ships within 1-2 Business Days

-

$24.99Ships within 1-2 Business Days

-

$157.99Ships within 1-2 Business Days

-

Teknipure

SKU: TZ1PCS2

TekniZorb Lightweight Polyester/Cellulose Nonwoven Cleanroom Wipe, 9" and 12" sizes

$18.99Ships within 1-2 Business Days -

Teknipure

SKU: TZ199STERILE

TekniZorb 9 in. x 9 in. Sterile Poly/Cell NonWoven Cleanroom Wiper, 100/bag, 30 bags/case

$9.99Ships within 1-2 Business Days -

$25.99Ships within 1-2 Business Days

-

$38.99Ships within 1-2 Business Days

-

$26.99Ships within 1-2 Business Days

-

$6.99Ships within 1-2 Business Days

-

Teknipure

SKU: TC2PL1-99BLACK

TekniClean Polyester Knit Cleanroom Inspection Wipe, 9 x 9 in., 150/bag, 10 bags/case

$31.99Ships within 1-2 Business Days -

Teknipure

SKU: TS2PL2I70-9

TekniSat 70% IPA Laser Sealed Edge Polyester Knit Cleanroom Wipe, 9 x 9 in.

$139.99Ships within 1-2 Business Days -

$27.99Ships within 1-2 Business Days

-

$124.99Ships within 1-2 Business Days

-

Teknipure

SKU: TC2MFU1-9

TekniClean Microfiber Cleanroom Wiper, Ultrasonic Sealed Edge 9 x 9 in., 10 bags/case

$78.99Ships within 1-2 Business Days -

Teknipure

SKU: TZ1PCS1B-9

Polyester/Cellulose Nonwoven Blue Cleanroom Wipe, 9 x 9 in., 300/bag, 10/bags/case

$27.99Ships within 1-2 Business Days -

Teknipure

SKU: TZ1PCS1-361000

Polyester/Cellulose Nonwoven Cleanroom Roll, 36 in. x 1000 ft., 1 roll/case

$369.99Ships within 1-2 Business Days -

$374.99Ships within 1-2 Business Days