Description

TekniClean Sterile Polyester Knit Cleanroom Wiper with Laser Sealed Edges, 9" x 9"

Clean Aseptic Cleanrooms quickly and easily!

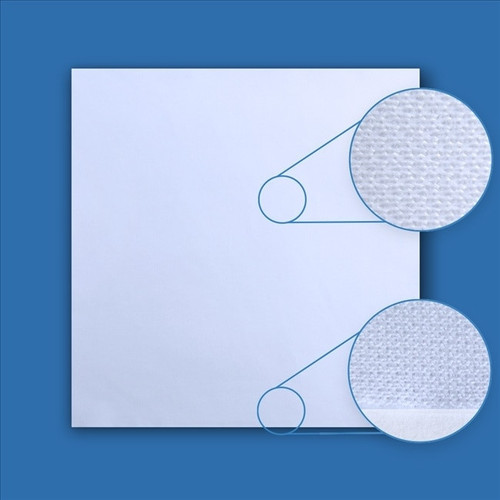

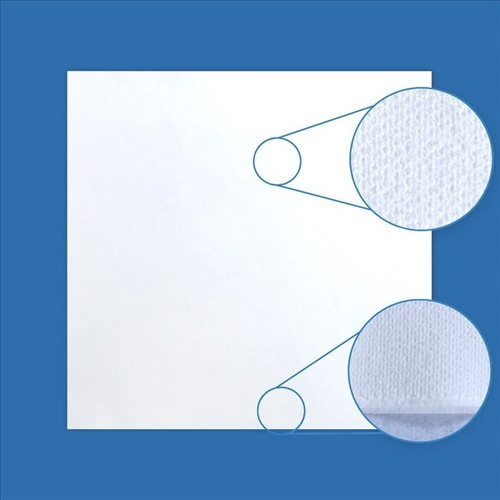

- 100% High Strength Polyester fiber (continuous filament, double knit, 140 g/m2) resulting in ultra low particle and fiber generation. Soft texture will not scratch sensitive surfaces.

- Laser Sealed Edges on all sides to minimize fiber release. Laser Sealed Edges provide effective contamination control in critical environments and offer the best value.

- Gamma Irradiated Sterile through Cobalt 60 processing. Ideal for cleaning pharma fill centers, sterile suites microbiological labs and more.

- Works well with IPA and other cleaning solvents.

- Solvent safe double bag cleanroom packaging. Compatible with ISO Class 4-5 (Class 10-10000) environments.

- Size 9 in. x 9 in. Packaged: 20 wipes per bag, 25 bags per case.

What are the Types of Cleanroom Wipe Border/Edge Seals?

Cleanroom Wipers have sealed edges to prevent particle and fiber generation and provide a clean wipe. Cleanroom wipes can have a sealed border, a sealed edge, or a cut edge. The level of fiber and particle release will depend on your wipe seal. Note the difference in sealing the border around the wipe (most clean) or just the wipe edge (most common).

Cleanroom Class 1-10 (ISO 3-4): Sealed Border

Sealed Border wipers are the cleanest & best performing choice for your most critical tasks. Maximum cleanliness and fiber control.

A proprietary process using pressure & heat is used to create a border seal for optimum fiber and particle retention, resulting in a 5mm Ultrasonic Border Seal around the border of the wipe. The most rigorous washing and border sealing process for applications requiring maximum particle and fiber retention.

Cleanroom Class 10-100 (ISO 4-5): Sealed Edge

Sealed Edge wipers are exceptionally clean and a common critical task wiper. The difference over border seals is that only the edging of the wipe is sealed instead of a border around the edge of the wipe. A Laser Sealed Edge is provided on all sides for maximum fiber and particle retention. A Ultrasonic Sealed Edge involves a process using pressure & heat to create an ultrasonic seal for fiber and particle retention. Ultrasonic Sealing is superior to Laser Sealing as it results in a softer edge, and lower carbon levels. Soft sealed edges retain all fiber in scratch sensitive applications.

Cleanroom Class 100-10,000 (ISO 5-7): Hot Knife or Laser Sealed Edge

Knit (Woven) Wipers

Light weight with a Laser Sealed Edge to provide effective contamination control in critical environments and offer the best value. Low levels of contamination and superb particle removal and retention make this the ideal wiper where economical and effective cleaning is required. Most economical critical use knit wipers.

Non-Woven Wipers

Excellent absorbency and particle removal in controlled environments. Commonly used in many general cleaning applications. Higher levels of fiber and contaminants than knit wipers. Excellent choice for economical cleaning & spill pick-up, and wrapping controlled surfaces. These non-woven wipers have Hot Knife Sealed Edges.

This edge type is intended for high-volume and large size applications.